A few days ago, the 2021 Buick GL6 model of SAIC-GM achieved mass production and went on sale. Innovative interior design is one of the highlights of this model, including the interior instrument panel. The GL6 model’s instrument panel skin is the combination of Dawn Polymer’s manufacturing technology of advanced thermoplastic elastomer and Kraton’s IMSS™ (Injection Molded Soft-Skin) technology. The GL6 is the first mass production car in the world to equip with this revolutionary material.

SAIC-GM 2021 Buick GL6 Model

SAIC-GM 2021 Buick GL6 Model Interior

IMSS™ material is an ultra-high flow thermoplastic elastomer. Unlike the traditional PVC soft skins, HSBC-based soft skins allow injection molding of large thin wall soft skin parts such as instrument panels. The material has no added plasticizer, phthalates, or cross-linking agents which can make the automotive interior low smell, low VOCs, and low fogging volatiles with better aging, subsequently improved safety performance, and lower specific gravity. In addition, IMSSᵀᴹ technology can further systematically reduce the production cost of the automotive interior skins which is in line with the general trend of the sustainable development of the automotive industry.

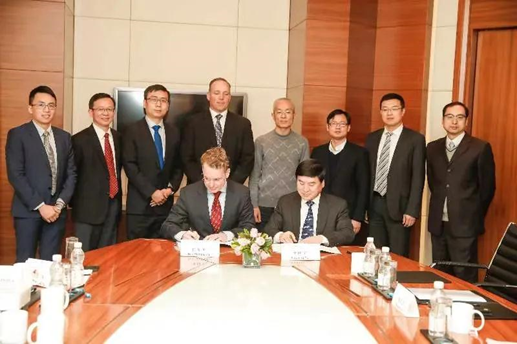

IMSSᵀᴹ technology was pioneered by Kraton Corporation, a leading global producer of styrene block copolymers, specialty polymers, and high-value performance products derived from renewable resources. In early 2019, Kraton and Dawn polymer signed a technology transfer agreement. Dawn polymer was authorized to use IMSSᵀᴹ technology free of charge, and has the right to make technological improvements, produce, and sell IMSSᵀᴹ modified materials in China. After two years of cooperative R&D, significant progress was made in the refinement and implementation of this technology.

According to Alberto Fornaro, Kraton’s Market Development Director: "It's a growing trend in the auto industry to introduce soft skin replacing hard plastic interiors. IMSS technology offers considerable cost and performance advantages over the existing soft skin technologies, with a better sustainability profile.”

Since the inception of the project, IMSS™ technology has undergone the rigorous material test and parts testing and achieved excellent performance. The first car model equipped with IMSS™ technology was into mass production which indicates that the IMSS™ technology has gained full validation from major stream automotive OEM producers and is now recognized as a superior better replacement to PVC slush molded instrument panel skins.

Joseph Zhu, director of IAC China Technology Center stated that: "In the increasingly competitive environment of the automotive industry, IMSS™ technology can help reduce the production cost of the interior skin, while providing better and innovative product performance, in response to the emerging industry requirements. This innovation will have a profound impact on the present and future development of the interior industry."

Being the first company in the world to apply this technology underscores the attention SAIC-GM places on the consumer experience. A Director at SAIC-GM Pan Asia Technical Automotive Center said, “SAIC-GM has been committed to the application of the innovative materials technology to provide consumers with a more comfortable and environmentally friendly driving experience. Compared with traditional PVC skin, IMSS™ can further improve the automotive interior environment and make the odor low and VOC less volatile."

Since being presented to the automotive industry, this technology has received positive attention and recognition. On June 10th, 2020, IMSS™ Technology received a Ringier Technology Innovation Award – Plastics Industry in the Raw Material & Additives category. At the same time, IMSS™ technology was also recognized by The European Rubber Journal’s (ERJ) in the Elastomers for Sustainability (ES4) contest as a viable alternative to slush-molded PVC in the automotive instrument panel skin applications.

For the debut of GL6 Bob Hall, Kraton’s Global Marketing Senior Director, commented that: "It is exciting to see the successful application of IMSS™ technology equipped in the GL6 model with mass production. With recognition in the marketplace, we believe that there will be more car models equipped with IMSS™ technology. We expect further market growth."

"As the largest TPV supplier in the automotive industry in China, Dawn Polymer are committed to providing innovative elastomer technology solutions for the automotive industry. Kraton IMSS™ technology can further expand Dawn's products line and lay a good foundation for Dawn's entry into the TPE-S market. The success of GL6 Model is also an important milestone in the success of the partnership between Kraton and Dawn" said Tian Hongchi, General Manager of Dawn Polymer.