“Dawn's skin-friendly masks are fluffy, soft, and breathable!" A few days ago, the "skin-friendly" mask series products launched by Dawn Mold Plastic Company have been favored by the market. "Compared with the previous masks, wearing them is particularly skin-friendly. I like them very much!" A customer from Beijing said.

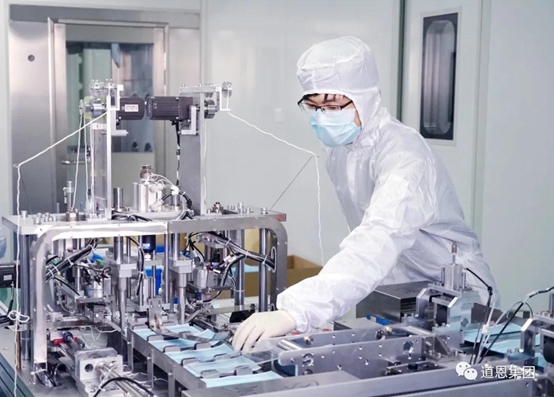

In March 2020, Dawn Mold Plastic Company urgently built a 100,000-grade dust-free production workshop for medical masks, introduced 5 mask production lines and supporting equipment for inspection and disinfection, and got Class II Medical device production qualification with a daily output of more than 400,000 masks at the most strenuous moment of fighting against Covid-19, contributing to the prevention and control of Covid-19 and the resumption of work & production, and it finally has been a "National Key Guarantee Anti-epidemic Enterprise".

Under the epidemic situation, the industrial chain has become an "epidemic" chain. Prior to this, Dawn’s melt-blown polypropylene as special material for masks with hard-core performance in fighting against COVID-19 demonstrated Dawn’s Love for the family people and the nation. After launched the mask production line Dawn Mold Plastic Company started to extend, repair, and strengthen the chain without stopping, and quickly introduced 4 melt-blown fabric production lines. “The quality of raw materials is controlled from the source, and the production process is checked layer by layer to effectively ensure the quality of masks.” said Mou Xiangmei, marketing and sales director of Dawn Mold Plastic Company.

The joint of Shandong SWT New Material Co., Ltd into Dawn not only open up the core link of the entire industry chain of medical and health nonwoven materials, but also provide high-quality raw materials for the upgrade of Dawn Mold Plastic Company's mask products. As an industry-recognized "Soft nonwoven fabrics expert", Dawn-SWT independently researched and developed a new liquid cotton nonwoven fabric, which is fluffy, soft, skin-friendly, breathable, and non-irritation, reaching the international leading level. Mou Xiangmei said, "This new type of material is used in the inner layer of our Skin-friendly masks."

At the beginning of 2021, the domestic epidemic is facing the risk of a second outbreak as the global COVID-19 continues to raging. Dawn Mold Plastic provides disposable protective masks, reusable sanitary masks, disposable medical masks and disposable medical surgical masks with guaranteed quality and quantity, presenting consumers with diversified products. "The mask adopts two full-plastic nose strips with one of the two strips added in the middle. This double nose strips increase the breathing space, reduce the resistance, and also avoid the embarrassment for women when wearing a mask after wearing lipstick," said Mou Xiangmei. The effect is determined by careful effort and these details make the protection more intimate, more comfortable, and healthier.

Last September, Dawn Mold Plastic Company successfully passed the "EU CE" product certification and was short-listed for the medical supplies "white list" of the Ministry of Commerce, marking that Dawn masks have obtained the "passport" to enter the European market. Mou Xiangmei said, "German customers are very interested in our skin-friendly masks. We are negotiating to build a European sales center to contribute to the global fighting against COVID-19."

At present, the Dawn precision mold and plastic product deep processing project has been completed, and the high-end medical and health parallel two-component nonwoven fabric production project will start construction. Dawn Group takes the opportunity of building an anti-epidemic asset industrial park to strengthen the innovative research and development of raw materials for mask fabrics and medical & health material applications, undertakes the task of fighting against COVID-19 as always, helps to win an overall victory and protect the lives, health, and safety of people.