On February 3rd, "The Road to a Strong Province" column of Qilu One Spot Client-side from Qilu Evening News focused on Dawn's new polymer materials industry titled "Located in Longkou Town, The new material enterprise of Dawn Polymer Ranked the 3rd in the world".

Dawn polymer is a national high-tech enterprise engaged in the research and development, production and application of new polymer materials such as thermoplastic elastomers, modified plastics, and biodegradable plastics. The key core technology won the second prize of the National Science and Technology Invention. A variety of products such as thermoplastic elastomer TPV and melt blown materials have entered the global competitive arena. During the COVID-19, Dawn Polymer used the technology to empower the anti-epidemic and demonstrated Dawn's love for family and the country.

"This is our TPV (thermoplastic vulcanized rubber) intelligent chemical factory of Dawn Polymer, which realizes the Internet of Things, CNC, and quantity control of the workshop from the whole process. Each workshop is paperless, and the process can be controlled from the central control room." In an interview, Wang Enli, manager of the assessment department of Dawn Polymer, said, “Through this smart factory, the product quality of TPV (thermoplastic vulcanizate) has been steadily improved. In addition, all data can be exported to a clear data table, and we can carry out key management and control. Various alarms in the middle process can be adjusted and controlled from the data center."

Tian Hongchi, General Manager of Dawn Polymer, said, "Dawn officially entered the industrialization of TPV (thermoplastic vulcanized rubber) in 2006. Actually, Dawn developed this industry amidst domestic doubts. Many people did not believe that it was possible to incubate such an internationally advanced product in a small town like Dawn. It was incredible.”

Tian Hongchi told Qilu One Spot column from Qilu Evening News reporter, " under the circumstances of that year, only 4 countries in the world had this production technology. Dawn succeed and became the fifth in the world. This product does have a lot of vitality. The technology is advanced and the market application capacity is very huge. It is an important way to solve the non-recyclable and black pollution of traditional rubber. Countries all over the world attached great importance to the R & D and ownership of this technology.”

"In 2008, many of the top 500 companies in the world knew that Dawn succeeded, so they wanted to come over and buy back this technology. At that time, our chairman resolutely said that we need to develop our own national enterprises develop our own national industry and national technology. So, we refused them. We insist on independent innovation and R & D. Judging from today, we did succeed. At present, we are already far and away from the first in the country and we rank the third in the world.”

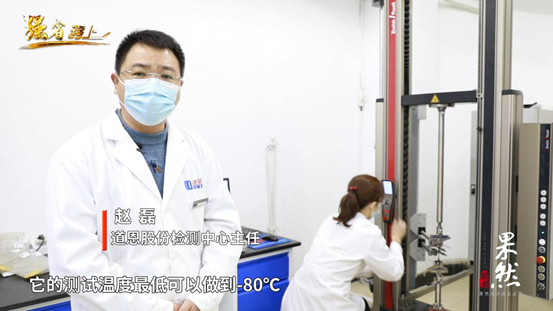

Zhao Lei, director of Dawn Testing Center, said, “Dawn Testing Center is a laboratory accredited by China CNAS. The test reports issued by us are mutually recognized internationally. This equipment is our high and low temperature universal tensile testing machine imported from Germany. Its test temperature can be as low as -80℃ and as high as 250℃. It can do some tests under extreme conditions.”

The hydrogenated nitrile rubber device with an annual output of 3,000 tons is independently designed by Dawn and is also a device that breaks the international monopoly. Currently, there are two companies in the world, Zeon of Japan and LANXESS of Germany that can produce HNBR. It can be said that China has broken the international monopoly.

Tian Hongchi said, "Dawn is the manufacturer and researcher of raw material. We have some core products that form a closed loop of the industry chain. For example, from melt blown material to melt blown fabrics and then to masks. We still focus on the materials. That is, melt blown pp materials. Our biggest starting point for making melt blown fabrics and masks is to promote our upstream material research and development capabilities through downstream applications.”

"Dawn has always been focusing on major national industrial needs and major livelihood needs for product development and sales. During the national "14th Five-Year Plan" formulation process, Dawn also focuses on the national "14th Five-Year" strategy and carry out its research and development to make greater contributions to the development of our Shandong new materials industry." Tian Hongchi's words demonstrate Dawn's responsibility on the road to a strong country.