On the evening of December 25th, the KN95 mask production line was successfully put into production in the mask production workshop of Dawn Mold Plastic Co., Ltd., a national key guarantee enterprise for epidemic prevention and control. It was reported that the two newly launched production lines had a daily output of 240,000 pieces of willow-leaf and folding KN95 masks. This marks that Dawn Group's mask supply chain has been forged and extended, and it can contribute more high-quality epidemic prevention materials to the society.

At the beginning of the outbreak of COVID-19, Dawn Group focused on the production and supply of mask raw materials. Subsequently, it quickly formed a whole industrial chain from spunbonded materials and melt-blown materials to spunbonded fabrics and melt-blown fabrics, and then to masks". In the face of the epidemic, it ensured the industrial chain and supply chain truly to become the anti-epidemic chain.

At present, the focus of Chinese epidemic prevention and control has changed, orders for the entire industrial chain of mask products have surged, and orders for related products have been scheduled until the first quarter of 2023. "We have 4 key guarantee enterprises for epidemic prevention and control across Shandong Province and China. When the country and society need it, we will surely increase the production capacity and guarantee the supply." Yu Xiaoning, chairman and president of Dawn Group, said.

According to reports, non-woven fabrics for masks are generally divided into three layers, which is the so-called SMS structure. The inner and outer 2 layers are spunbonded layers, supporting the entire non-woven fabric structure. The middle layer is melt-blown layer, which is mainly to isolate droplets, particulate matter, acid mist, microorganisms, etc. "Whether it is raw materials or non-woven fabrics, there are contributions from Dawn products."

As a leading enterprise in the R&D and promotion of polypropylene spunbond materials in China, Dawn Group is committed to the R&D, promotion, customized production and marketing services of non-woven materials. It played an important role in the fight against the "SARS" in 2003 and the COVID-19. Tang Lingling, Marketing Director of Dawn Chemicals, said, "Downstream customers have a relatively high start-up rate, and the sales volume of spunbond materials this month increases significantly compared with last month. It will be delivered one week later than the order placed, and the spunbond material is in great demand! "

Dawn Polymer increased its production capacity to ensure the supply of polypropylene meltblown special materials

Dawn Polymer increased its production capacity to ensure the supply of polypropylene meltblown special materials

Melt-blown fabric is called the "heart" of masks, and its raw material is Dawn polypropylene melt-blown special material. "We are an important supplier of polypropylene melt-blown special materials in the world. We have been deeply involved in this field for 20 years and owned the world's leading self-developed preparation technology. "Wu Di, deputy general manager of Dawn Polymer, said that the company could produce, supply with high quality at any time as long as the customers had needs by relying on leading preparation technology and smooth emergency mechanism.

In the early outbreak of COVID-19, Dawn Mold Plastic Co., Ltd. urgently built a dust-free production workshop of 100,000-level medical masks, introduced 5 mask production lines, and some inspection and disinfection supporting equipment, and obtained the qualification for the production of second-class medical devices. During the same period, Dawn Group acquired SWT Company that was hailed as a "nonwoven fabric softness expert" by the industry, which meant that it had further opened up the whole industrial chain of nonwoven materials for medical and sanitary use.

Launching Ceremony of Dawn-SWT Base in Longkou

" Dawn-SWT independently developed and produced the new aqua cotton non-woven fabric which has reached the international leading level." Zou Binghuan, general manager of Dawn-SWT, said that the inner layer of the mask made of this new material had unique advantages such as fluffy, soft, skin-friendly, breathable, and non-irritating. "The quality of raw materials is controlled from the source, and the production process is checked at every level, which effectively guarantees the quality of masks."

When the fight against the epidemic was most strenuous, Dawn Polymer and Beijing University of Chemical Technology jointly undertook the "Key Technology and Industrialization of Reusable Protective Masks" of the Ministry of Science and Technology and the "Research on the preparation technology and industrialization of melt-blown grade polypropylene material that can be stored for a long time and can be used repeatedly" of Beijing Municipal Science & Technology Commission and other emergency research and development topics. It also participated in the drafting of the "Group Standard for Reusable Civilian Masks", and contributed scientific and technological strength to the realization of the strategic reserve of epidemic prevention materials.

"Qilu Evening News" focused on the development of reusable masks

"We urgently launched the KN95 mask production line to alleviate the shortage of high-grade protective masks." Zhang Jiakai, Marketing Director of Dawn Mold Plastic Co., Ltd., said that they had played the advantages of coordinated operations from equipment procurement to logistics transportation, and to installation and commissioning, and even achieved the goal of adjusting and testing the equipment and putting into production on the same day. “Only by manufacturing the products early can we make contributions early."

Mask production workshop of Dawn Mold Plastic Co., Ltd

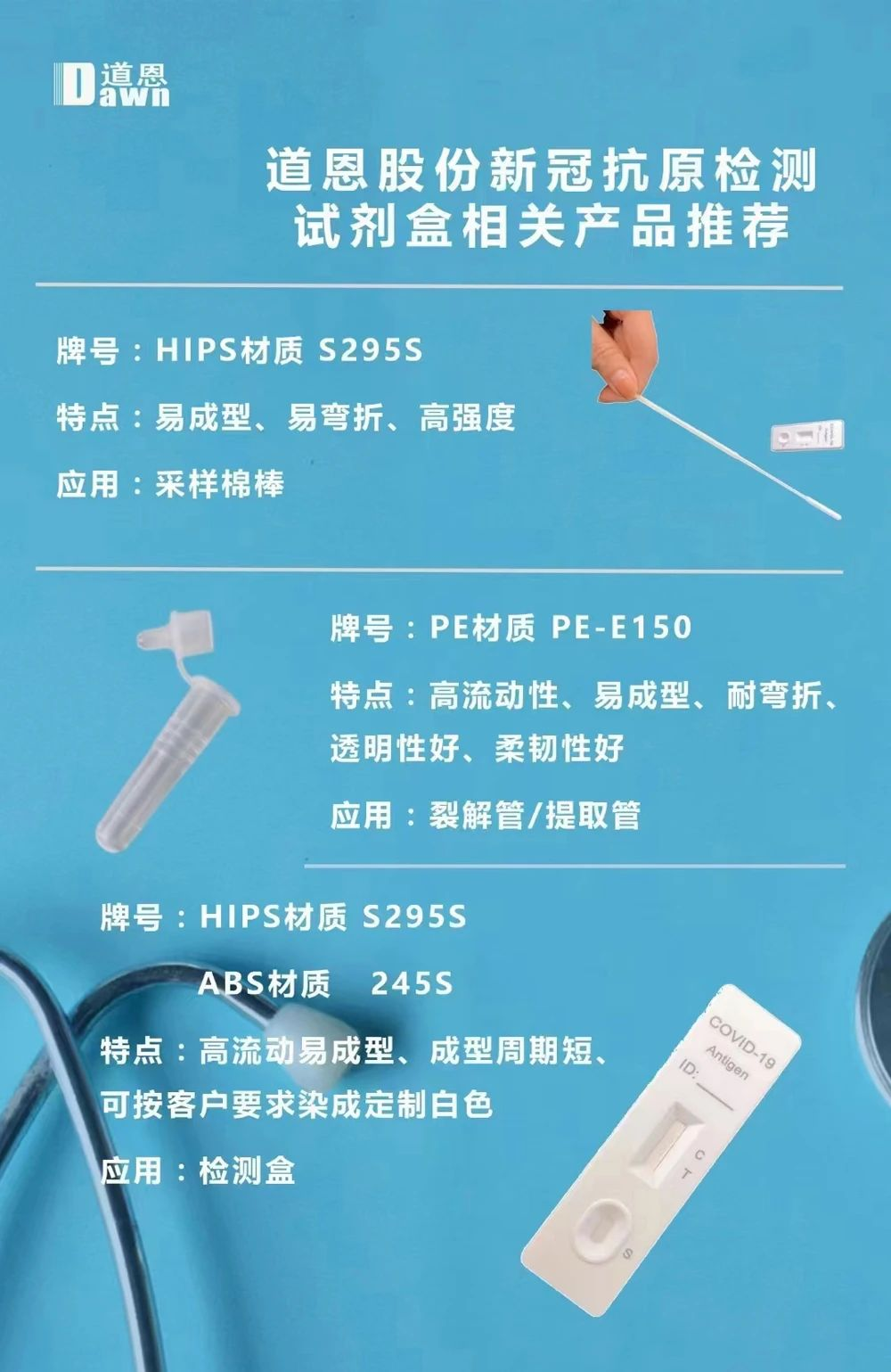

In addition to the series products of the mask industrial chain, Dawn Polymer has also developed and launched related products of antigen detection kits. "The need of the society is the direction of our efforts." Deputy General Manager Wu Di said, "Many customers have used it in batches, and the market feedback was good."

Related product grades of antigen detection kits

Under the new epidemic prevention situation, a consensus has been formed for all people to wear masks. Chairman of Dawn Group Yu Xiaoning said that Dawn Polymer would run at full capacity, speed up production, open up the supply of the entire industrial chain, meet market demand with maximum production capacity, and fully support and ensure the public “to be the first person responsible for their own health". "Continuously improving the energy level of the anti-epidemic supply chain is the vivid practice of building Dawn's 'industrial chain, product chain, and enterprise chain', which conforms to the spirit of 'improving the resilience and security level of the industrial chain and supply chain' of China to maximize the protection of people's life safety and health.