On February 23rd, 5 departments including the National Development and Reform Commission issued a notice to release the list of newly recognized and all national enterprise technology centers in 2021 (the 28th batch). The reporter found that among the list of all national enterprise technology centers, Shandong province has 185 on the list, accounting for 11.5% of China, and far aheading of other provinces.

The 185 national enterprise technology centers are all excellent masters, creators of "Shandong Province with Good Products", and leaders of "vigorous Shandong Province". In Longkou city, there were three companies on the list, and the Technology Center of Dawn Polymer accounted for one of them. At the end of February, the reporter walked into Dawn National Technology Center to explore the essence.

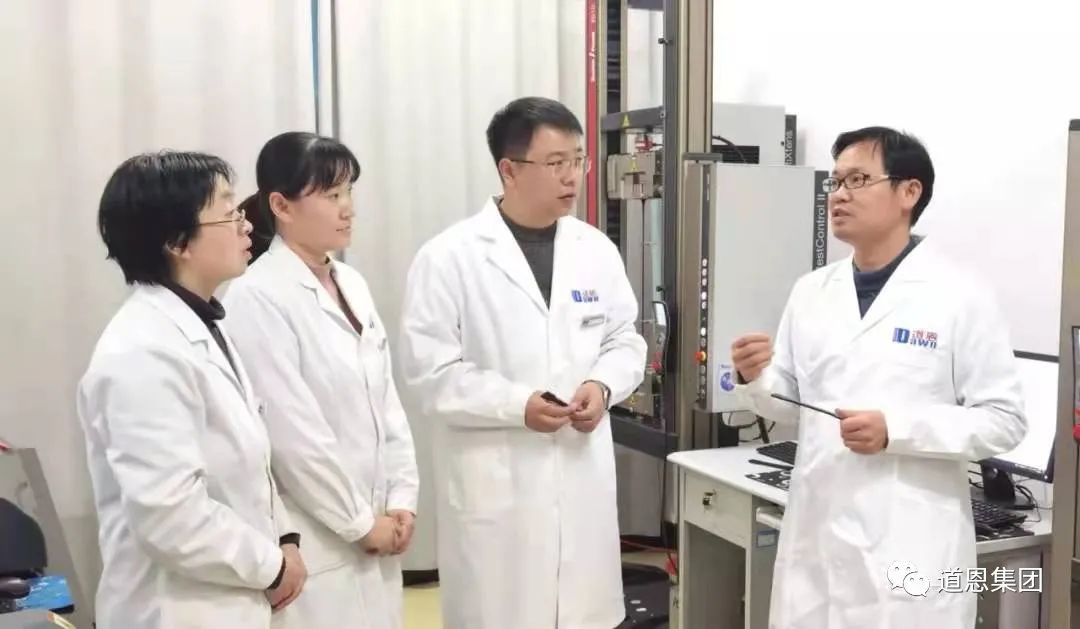

"The low temperature can reach -80 ℃, the high temperature can reach 250 ℃, and the test accuracy is the highest in the world." Zhao Lei, the testing director of Dawn Polymer’s national enterprise technology center, introduced that it was a high-precision high-low temperature universal tensile test customized from Germany, which was mainly used for performance testing of aerospace materials at extreme temperatures.

The impact speed is the highest in the world, and the impact speed can reach 24m/s; the British high and low temperature box is equipped to simulate the explosion test of the instrument panel airbag in extremely cold weather or tropical regions. Zhao Lei said that it was a high-speed multi-axis impact testing machine imported from Italy, which can mainly used for instrument panel blasting experiments.

The above two types of equipment are the top machines of Dawn Polymer Technology Center. The laboratory with an area of 1,500 square meters was quiet and clean, and more than 100 sets of top experimental and testing equipment imported from abroad with a value of CNY 120 million were arranged in an orderly manner.

Tian Hongchi (1st from the right), a national key talent engineering expert and general manager of Dawn Polymer, guiding the work in the technology center

Dawn Polymer Technology Center, founded in 1998, includes material analysis and testing laboratory, plastic material mechanics laboratory, rubber material mechanics laboratory, material durability laboratory, comprehensive laboratory, finished product verification laboratory and sample preparation room. With a heavy "golden signboard", it was the first batch of laboratories accredited by the China National Accreditation Service for Conformity Assessment (CNAS). At the same time, it is also a public service platform for small and medium-sized enterprises in Shandong Province, providing free technical support and testing and inspection services for some small and medium-sized enterprises every year.

Innovation is the vitality of an enterprise, and high-end talents are the core. Dawn Polymer currently has 4 experts serving as members of 5 national standardization technical committees. Up to now, it has participated in the formulation and revision of more than 60 international standards, national standards, industrial standards, and group standards. It has the voice in the industry, demonstrating the technological innovation strength of Dawn Polymer. As the saying goes, experts grasp the essence while the nonexperts notice the surface. In addition to high-end equipment, the technical center also has an efficient management system unknown to outsiders. Zhao Lei told reporters that the system was the LIMS information management system independently developed by Dawn.

Zhao Lei introduced LIMS system to customers

In order to make it clear to reporters, the sample receiver took out a bag of raw materials marked with a QR code and performed a simulated operation. On the computer, the receiver filled in the items to be tested on the LIMS system and directly printed the QR code. The reporter saw that all the information of the sample was recorded on the QR code, including the sample name, model, batch number, vehicle platform, and other information. After the sample arrived at the laboratory, the receiver scanned the QR code with a scanner to complete the receipt. It could be seen that each machine was equipped with a separate code scanning gun, and all the preparation information could be seen by scanning the QR code during sample preparation, and the whole process can be run paperless.

Zhao Lei introduced that the whole process from sample entrustment, sample preparation, and testing was realized by scanning QR code and automatic information capture. And they can view the status information of the order in the system in real-time, and realize real-time data transmission. In recent years, Dawn Polymer has formed a quality management model of "Four Quantities, One Efficiency and Two Rates" of strengthening the foundation, injecting into the source, enriching the wings, and promoting the improvement, of which the technical content ranks first. "LIMS big data system provides accurate and efficient services for subsidiaries in Dawn Polymer to stabilize product quality, improve R&D efficiency, reduce R&D costs and achieve production control," Zhao Lei said.